How is our PVC flooring roll produced?

Apr 16,2024

Apr 16,2024

266

266

FLAGLES PLASTIC

FLAGLES PLASTIC

How is Flagles' PVC flooring roll produced?

-

Step 1 Raw Material Preparation:

Mix specific chemical additives with PVC raw materials.

Heat the mixture to the appropriate temperature to make it pliable.

-

Step 2 Extrusion and Calendering Process:

Use an extruder to push the heated PVC compound through a die.

Press the extruded PVC material into a thin film using a double-roll calender.

-

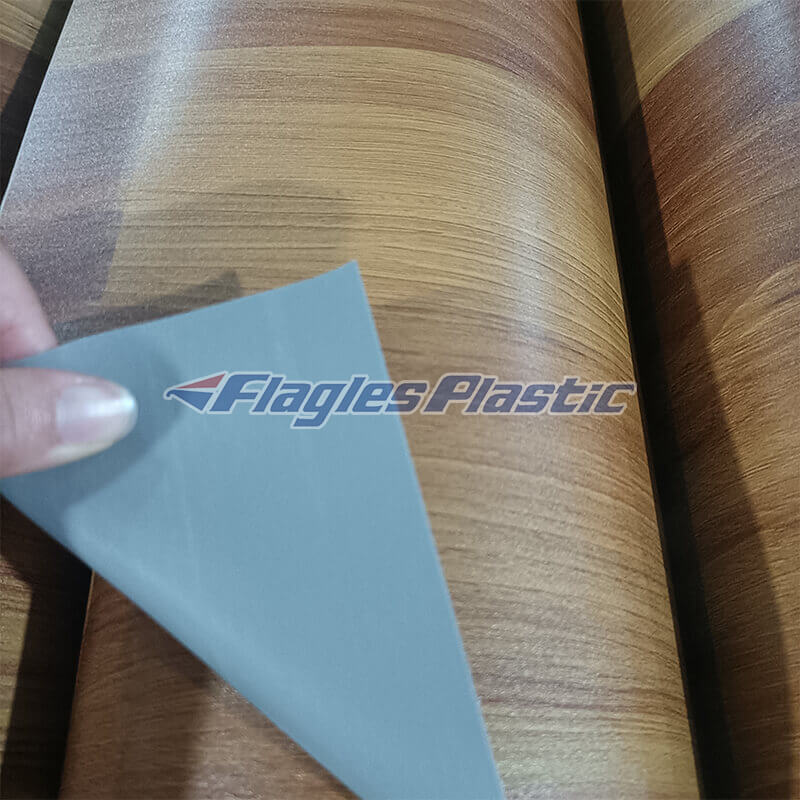

Step 3 Surface Treatment:

Emboss the surface of the PVC film with different textures if required using an embossing process to meet various decorative and functional needs.

-

Step 4 Post-Processing:

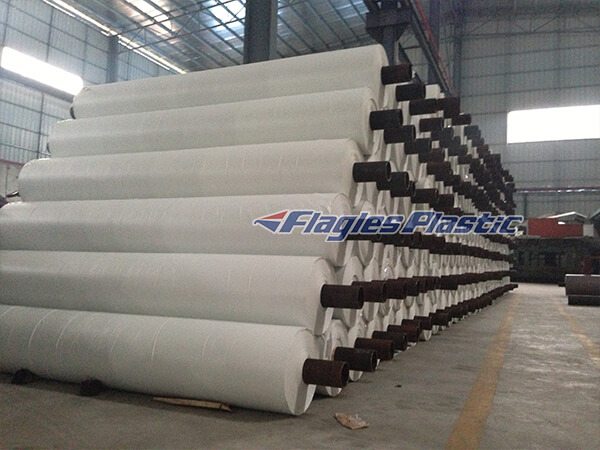

Cool the PVC film to solidify it.

Cut and wind it into a roll to produce a complete PVC film product.

-

Step 5 Printing

We use PVC films of different colors to print various floor patterns using printing equipment.

-

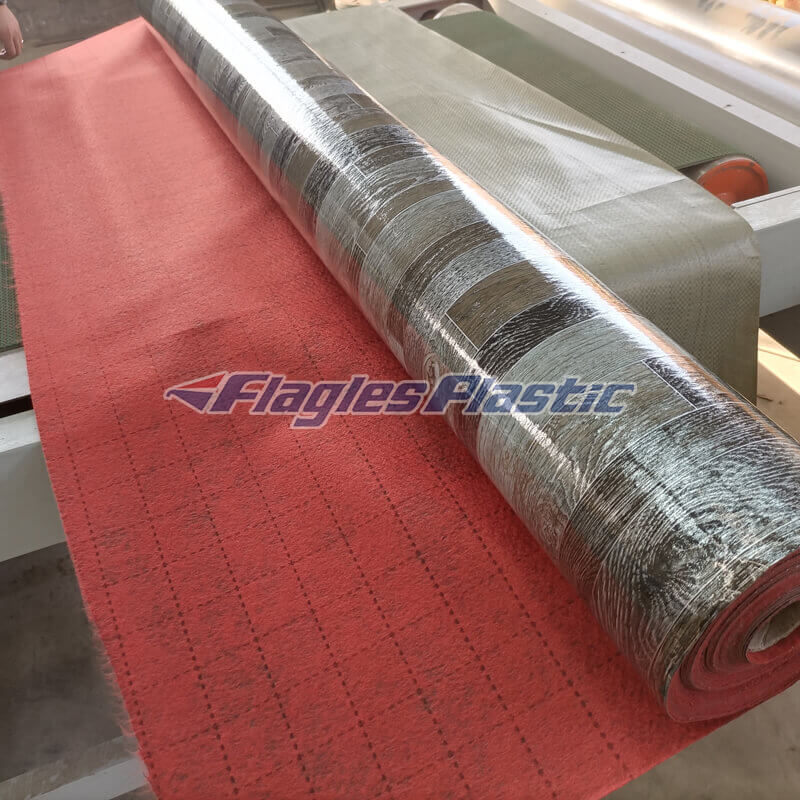

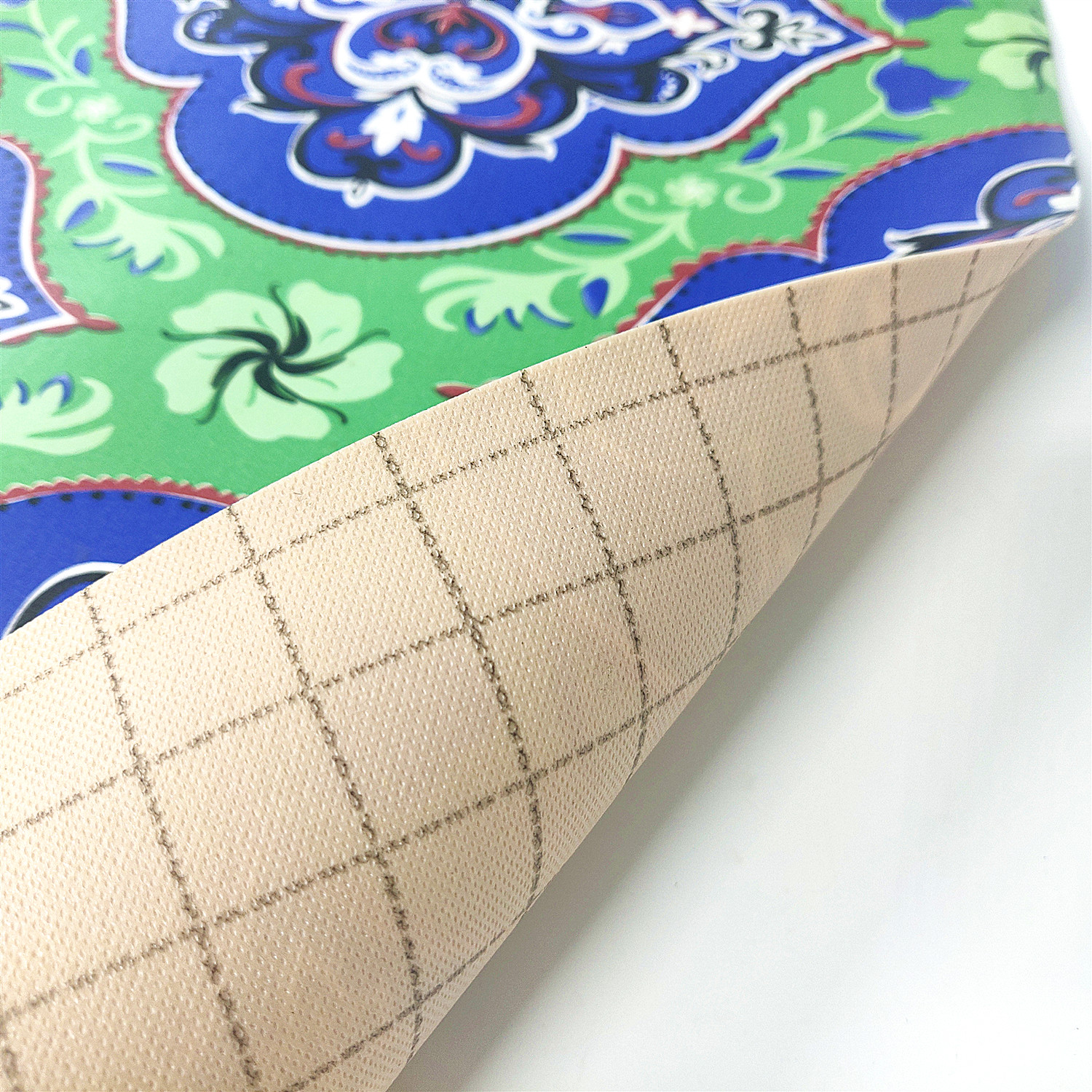

Step 6 Laminating:

Using laminating equipment, we bond the protective layer, printing layer, and bottom layer together to form rolls of plastic flooring.

Home

Home

What is PVC Flooring Roll?

What is PVC Flooring Roll?  You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address